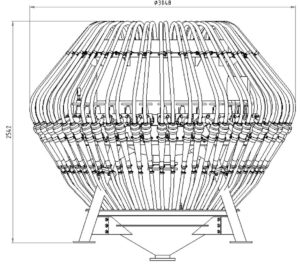

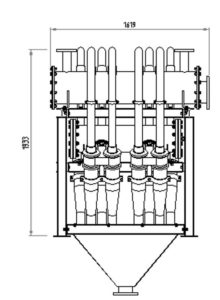

AKA-SPIDER are annular distributors, combining several hydrocyclones together in order to reach a requested process throughput.

Principle of operation

The hydrocyclones are connected to an inflow chamber (feed chamber) which is fed with the necessary amount of slurry at a calculated pressure. Each hydrocyclone is charged with the same pressure. The hydrocyclone overflows will be collected in an overflow tank, and the underflows in a separate underflow chute.

Design features and advantages

- Homogeneous and equal pressure distribution of the suspension on every hydrocyclone in operation

- Equal flow distribution

- Customized design

- Available as annular or longitude distributor

- Available with rubber liner

- Reduced dead zone in the feed tank

- Different kind of shut off valves (butterfly valves, flat valves, bottom angle valves)

- Can be equipped with antiblocking filter AKA-STRAINER

Example drawings

Applications

- Minerals (e.g. Kaolin, Feldspar, Talcum, Chalk, Quartz, Gypsum, Bentonite, Zircon, Phosphate)

- Ores (e.g. Iron ore, Bauxite, Zinc ore, Tin ore, Manganese ore, Chromite ore, Niobium-Tantalite-ore)

- Chemical intermediates

- Alumina

- Sands

(Gemafreie Musik von www.frametraxx.de)

For more information:

GET IN TOUCH

Back to the overview:

GET BACK