AKA-SIZER type TAK can produce products with cut sizes up to 0.8 mm/800 μm.

Principle of operation

An optimum distribution of the upstream water via self-closing nozzle plate results in a homogenous classifying bed, which enables a precise separation. By varying the water feed, different cut sizes can be achieved. A special designed discharge regulation system controlled by the density of the fluidized bed, ensures a uniform cut size even in the case of fluctuations of the feed specification (grain size, concentration, capacity).

Design features and advantages

- Self-closing nozzles

- No dead zone above the discharge valves

- Special designed discharged dart valves

- Adjustable and sensitive density sensor

- Central feeding for an effective distribution into the tank

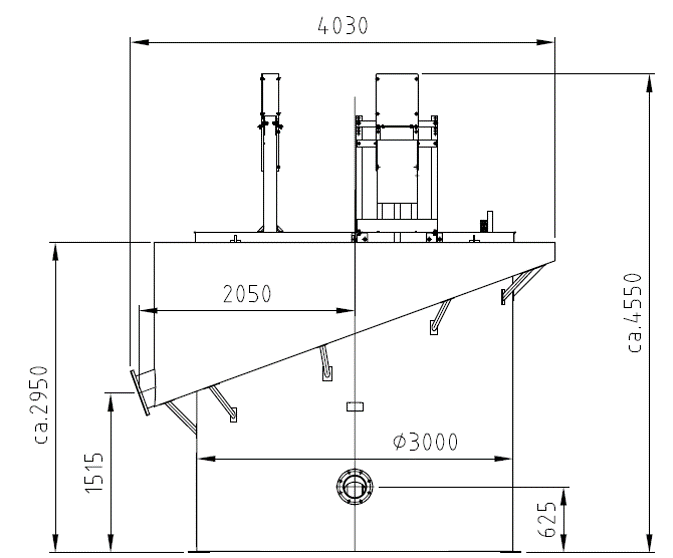

Example drawing

Applications

- Glass, foundry and industrial sands

- Phosphate

- Chromite

- Slag

(Gemafreie Musik von www.frametraxx.de)

For more information:

GET IN TOUCH

Back to the overview:

GET BACK